The development of many industries in our life is inseparable from the production of intermediate frequency induction heating furnace. Sometimes, some unimportant factors may lead to a big gap. For example, the intermediate frequency melting furnace, which is the premise, today we will learn about "the safety operation of intermediate frequency induction heating furnace for you to analyze the measures to reduce the raw materials of intermediate frequency induction heating furnace".

How to operate the medium frequency induction heating furnace in the process of processing can ensure the safety. The following is a brief introduction for you.

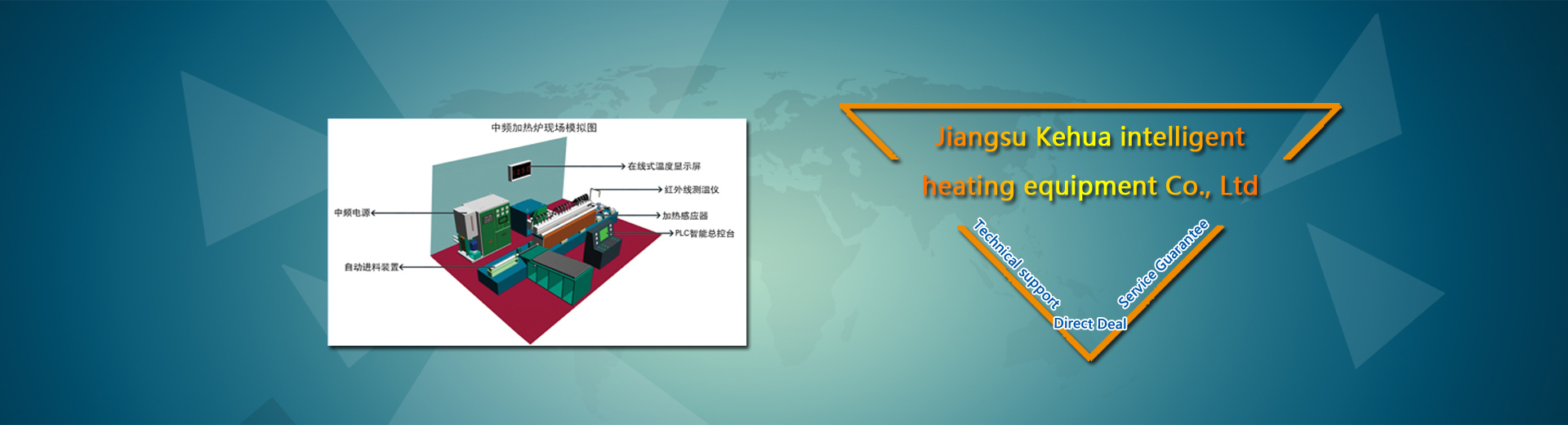

First of all, before starting the machine, a good inspection should be carried out, including the integrity of water cooling system, electrical equipment, inductor copper tube and other equipment.

Secondly, in the recommended use, we should pay attention to timely detection and repair. It is strictly prohibited to mix iron scraps and iron oxide in the furnace. The ramming crucible must be dense. When the melting loss is too deep, melting cannot be carried out in the pot.

Third, during charging, it is necessary to avoid hazardous substances mixing into the medium frequency as far as possible. The safety control of the medium frequency induction heating furnace shall be analyzed for you, and attention shall be paid to check that no cold or wet materials can be mixed into the liquid steel. Liquid steel is not allowed to be overfilled.

The basic production efficiency of the equipment can be improved by prolonging the continuous smelting time of the medium frequency induction heating furnace, and the smelting accuracy can also be improved by reasonable batching;

Reasonable smelting operation is the key to ensure the safety of production, and the quality of production can be ensured without problems by controlling the tapping temperature reasonably;

The smelting time can be shortened by reasonable arrangement of production, reasonable batching furnace, smelting operation and reasonable control of tapping temperature. The lining quality of medium frequency induction heating furnace and the integrity of smelting equipment are the basis of safety production, improvement of production efficiency, energy saving and consumption reduction. It is necessary to manage scientifically, take comprehensive measures and implement them practically, improve the production efficiency, increase the melting induction speed, reduce the raw materials of medium frequency induction heating furnace, and reduce the melting time, so as to achieve the purpose of saving electric energy.

The above is a brief introduction of "if induction furnace safety control for you to analyze the measures to reduce the raw materials of IF induction furnace". Our company also has many related products such as if induction furnace production, if you are more interested, you can contact us for more details.

Key words of this paper: reasonable improvement of medium frequency induction production