Our company is specialized in providing series resonance if power supply, full closed cycle cooling and other products and services. Do you understand the basic use of IF melting furnace equipment? In this paper, I will give you a specific introduction of this aspect. Let's take a look at the "working principle of intermediate frequency melting furnace to explain the basic use analysis of intermediate frequency melting furnace equipment for you"

The medium frequency melting furnace can deal with the traditional metal workpiece, which benefits from its good principle and performance. Now we will give you a brief introduction of its working principle.

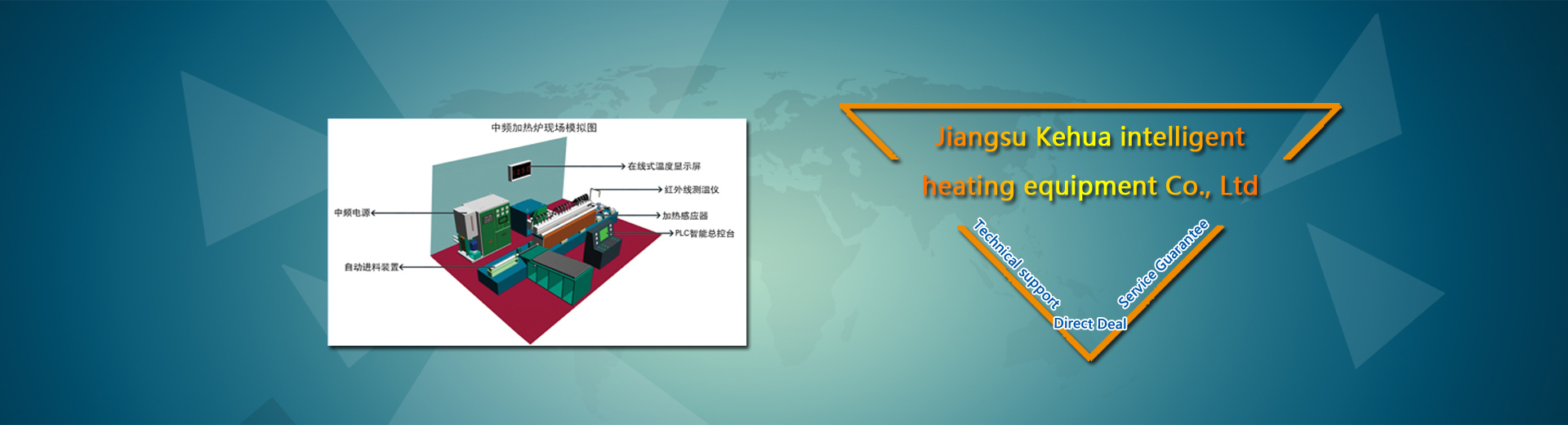

Under the control of the full control circuit, the alternating current is rectified to direct current, and after the reactor is regulated by smoothing, it becomes a constant direct current. Under the action of single-phase inverter bridge, the direct current will be inverted and become a single-phase if current. The load is composed of induction coil and compensation capacitor, which are connected into parallel resonance circuit.

Therefore, in case of failure of intermediate frequency power supply, it is necessary to make a reasonable judgment according to the situation, and make a comprehensive inspection of the whole system under the condition of power failure, including power supply, rectifier, etc. Reasonably determine the cause of the failure, and explain the working principle of the intermediate frequency melting furnace for you, and then solve the problem.

1. Before starting the medium frequency melting furnace equipment, it is necessary to check whether the equipment, system and copper tube of inductor are in good condition. If there is any problem, the furnace can not be started.

2. In case of furnace melting loss, and the repair has exceeded the regulations, smelting is strictly prohibited under the condition of too deep melting loss.

3. After the power transmission and opening of medium frequency melting furnace equipment, it is necessary to ensure that there is a special person in charge, and the inductor and cable cannot be contacted after the power transmission.

4. During charging, it is necessary to check whether there are any inflammable and explosive harmful substances in the furnace charge. If there are any, it is necessary to analyze the basic use of medium frequency melting furnace equipment in time. It is strictly prohibited to add cold and wet materials directly into the molten steel. When the molten liquid is full to the upper part, it is strictly prohibited to add large materials to prevent capping.

The content introduced above is about "the working principle of the intermediate frequency melting furnace explains the basic use analysis of the intermediate frequency melting furnace equipment for you". I think you will have enough understanding of this aspect after reading our introduction. In addition to this, we also introduce the brand series resonance if power supply, manufacturer, price, brand, totally closed water-cooling system and other contents in another article. Please pay attention!